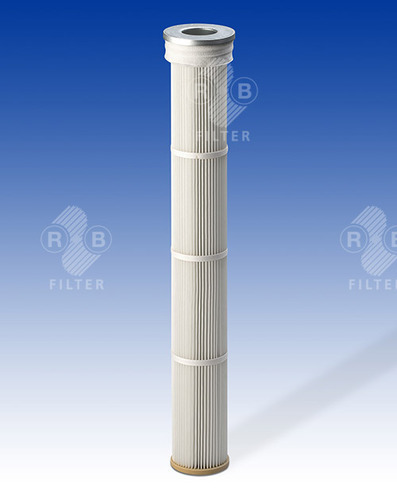

Pleated Filter Cartridge

Price 3000.0 INR/ Unit

Pleated Filter Cartridge Specification

- Shape

- Round

- Usage

- Industrial

- Size

- Standard Sizes

- Color

- White

- Warranty

- 1 year

Pleated Filter Cartridge Trade Information

- Minimum Order Quantity

- 5 Number

- Supply Ability

- 1 Number Per Week

- Delivery Time

- 1 Week

- Sample Available

- Yes

- Sample Policy

- Within a certain price range free samples are available

- Packaging Details

- As per client requirement

- Main Domestic Market

- All India

About Pleated Filter Cartridge

Pleated Filter Cartridge is suited for dealing with the final as well as pre filtration of different processes of gases and fluids. It is offered to clients with modish thermal bonding technology. In addition, it has high capacity to lessen the sediment particles, due to which the filtration efficiency gets increased. This Pleated Dust Filter Cartridge manufactured and supplied by us has layers of polypropylene, cellulose, polyester etc. Furthermore, it has optimum retention efficiency, large surface area and advanced filtration capacities. Due to the above mentioned properties, it ensures fine protection for downstream filters. High differential pressure as well as fixed pore structural design make it more demanded. This is essentially require for food & beverage applications. Supplied high-quality filtrating solution, known as pre filter cartridge boasts of maximum dirt holding capacity and ensures flawless function.

Pleated Filter Cartridge Advantages:

- Has additional support to provide protection from system pulsating.

- Capable to trap the impurities, with high efficiency and ease.

- Has optimized pleating density that contributes to consistent particle retention.

- Easily cleaned and reused, enabling cost-efficiency and ease in maintenance.

Properties of Pleated Filtration Cartridge:

- High retention capacity for better protection.

- Excellent mechanical and thermal strength.

- Provides good particle removal efficiency.

- Lightweight and high chemical resistance.

Advanced Pleated Filtration Technology

The pleated design of our filter cartridges increases the effective surface area, resulting in higher dirt-holding capacity and more efficient filtration. This innovation helps reduce maintenance frequency and extends the operational life of your equipment.

Flexible Sizing for Industrial Needs

Available in standard sizes and a round shape, our cartridges easily integrate into most industrial filtration systems. Their universal sizing makes replacement straightforward, reducing downtime and operational disruptions.

Quality Assurance from an Indian Supplier

As a leading exporter, manufacturer, and supplier based in India, we are committed to providing products that meet stringent industry standards. All filter cartridges are backed by a 1-year warranty, reflecting our confidence in quality and reliability.

FAQ's of Pleated Filter Cartridge:

Q: How do I install the Pleated Filter Cartridge in my industrial system?

A: Installation is simple: choose the corresponding standard size cartridge, remove the used unit, and insert the new round pleated cartridge into the designated housing following your system's guidelines. Secure all fittings for optimal performance.Q: What materials are used in these Pleated Filter Cartridges, and why are they white?

A: The cartridges use high-grade synthetic or cellulose materials for effective filtration, and their white color reflects purity and easy contaminant detection. These choices ensure compatibility with various industrial fluids and enhance quality monitoring.Q: When should I replace the Pleated Filter Cartridge during regular operation?

A: Replace the cartridge when you notice a significant drop in system pressure, or according to the recommended maintenance schedule of your equipment. Regular checks help maintain filtration efficiency and prevent process interruptions.Q: Where can I use these filter cartridges within my facility?

A: These cartridges are suitable for industrial filtration in sectors such as chemicals, pharmaceuticals, food processing, and water treatment. Install them in filtration housings dedicated to liquid or air purification processes.Q: What is the manufacturing process for the Pleated Filter Cartridge?

A: The cartridges are crafted by pleating filtration media into a round configuration, bonding the media securely, and assembling with durable end caps. Each unit undergoes rigorous quality checks before being offered as an exporter, manufacturer, and supplier from India.Q: How does the pleated design benefit industrial filtration?

A: Pleating maximizes filter surface area, increases dirt capacity, and improves flow rates. This ensures more contaminants are captured, resulting in longer cartridge life and fewer maintenance interruptions.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Dust Filter Cartridges Category

Dust Filter Cartridges 150 mm

Price 5500.0 INR

Minimum Order Quantity : 5

Color : All Color

Size : Standard Sizes

Product Type : Dust Filter Cartridge

Shape : Cylindrical

Vacuum Cleaner Cartridge

Price 3000 INR / Unit

Minimum Order Quantity : 5 Units

Color : White Yellow

Size : 130 mm

Product Type : Vacuum Cleaner Cartridge

Shape : Round

Dust Filter Cartridges 142 mm

Price 3000 INR / Unit

Minimum Order Quantity : 5 Units

Color : White

Size : 142 mm

Product Type : Dust Filter Cartridge

Shape : Round

Thread Filter Cartridge

Price 3000 INR / Unit

Minimum Order Quantity : 5 Units

Color : Black & White

Size : Standard Sizes

Product Type : Thread Filter Cartridge

Shape : Round

Branch Address

501, R.K.Constructions, Nr. Rosary School,

Phase-5, KPHB Colony, Hyderabad - 500 072

Phone/Fax: +91 40 40161398

M. Muralidhar (Territory Manager)

Hand Phone: +91 9704733366

|

R+B FILTER MANUFACTURING ENTERPRISES PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry